- Goederen van het merk YUHONG zijn al geëxporteerd naar meer dan 85 landen. Met meer dan 35 jaar ervaring, dankzij een strikt kwaliteitscontrolebeleid, uitstekende verkoopservice en tijdige levering. YUHONG heeft steeds meer nieuwe klanten gewonnen en steeds meer herhaalbestellingen van oude klanten gekregen. In de gedachte van de mensen van YUHONG: Kwaliteit is het allerbelangrijkste!

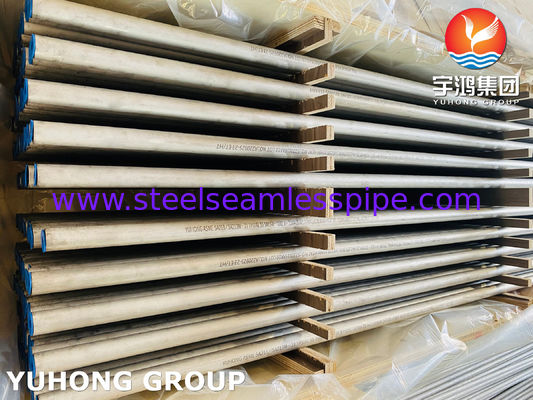

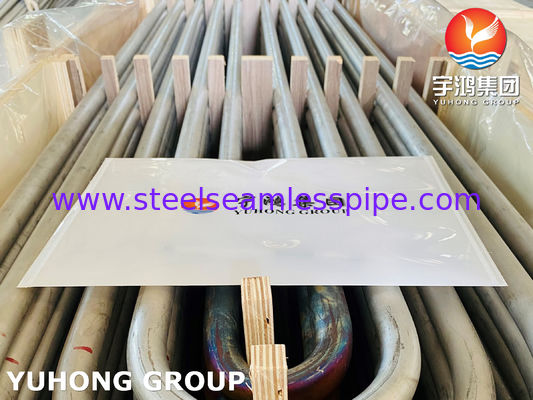

ASTM A213 TP316L Roestvrijstalen U-BUIS voor Ketel en Warmtewisselaar

Dit product is een hoogwaardige U-buis die speciaal is ontworpen voor ketels, oververhitters, warmtewisselaars en condensors die werken onder hoge druk, hoge temperaturen en corrosieve omgevingen. Vervaardigd uit ASTM A213 TP316L, een austenitisch roestvrij staal met een laag koolstofgehalte, biedt het superieure corrosiebestendigheid, sterkte bij hoge temperaturen en uitstekende vormbaarheid en lasbaarheid, waardoor het een cruciaal onderdeel is voor thermische efficiëntie en langdurige betrouwbaarheid van de apparatuur.

1. Chemische & Mechanische Eigenschappen

ASTM A213 TP316L Chemische Samenstelling (%)

|

| C |

Mn |

P |

S |

Si |

Cr

|

Ni

|

Mo

|

|

≤ 0,35%

|

≤ 2,00%

|

≤ 0,045% |

≤ 0,03% |

≤ 1,00% |

16%-18% |

10,00%-14,00% |

2,00%-3,00% |

Mechanische Eigenschappen

| Treksterkte |

Vloeigrens |

Rek (in 50 mm) |

Hardheid |

| ≥485 MPa |

≥170 MPa |

≥35% |

≤217 HB (Brinell) |

Beschikbaar Maatbereik

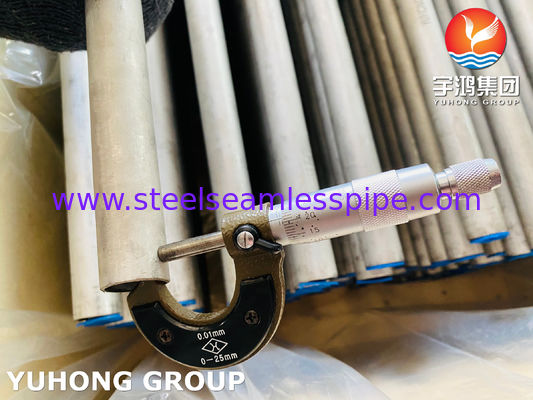

Buitendiameter (OD): Gemeenschappelijk bereik van 9,53 mm (3/8") tot 25,4 mm (1"), andere maten beschikbaar op aanvraag.

Wanddikte (WT): Gemeenschappelijk bereik van 0,8 mm tot 2,5 mm (overeenkomend met verschillende OD's).

U-Boog Radius (R): Aangepast volgens het ontwerp van de klant en de buizenbundelindeling.

Rechte Beenlengte: Precies gesneden volgens de tekeningen van de klant.

2. Belangrijkste Voordelen

- Superieure Corrosiebestendigheid

De toevoeging van Molybdeen (Mo) in TP316L biedt verbeterde weerstand tegen putcorrosie en spleetcorrosie in vergelijking met de 304-serie, waardoor het ideaal is voor omgevingen die chloride bevatten.

- Ultra-Laag Koolstofgehalte

De "L"-kwaliteit duidt op een maximaal koolstofgehalte van 0,030%, wat het risico op carbideprecipitatie tijdens het lassen en blootstelling aan het sensibilisatietemperatuurbereik (425-860°C) minimaliseert, waardoor intergranulaire corrosie wordt voorkomen.

- Uitstekende Eigenschappen bij Hoge Temperaturen

Behoudt een goede mechanische sterkte en kruipweerstand bij verhoogde temperaturen, waardoor de structurele integriteit tijdens langdurig gebruik wordt gewaarborgd.

Geavanceerde buigtechnieken zorgen voor een uniforme wanddikte, geen rimpeling of overmatige verdunning bij de U-bocht. Het gladde binnenoppervlak minimaliseert de drukval en handhaaft een consistente warmteoverdrachtsefficiëntie.

3. Belangrijkste Toepassingen

Warmtewisselaar (Shell-zijde minder corrosief) —— Om thermische uitzetting te hanteren

Condensor / Zeewaterkoeler —— Bestand tegen chloride-ionen corrosie

Ketel / Oververhitter —— Sterkte bij hoge temperaturen & oxidatiebestendigheid

Petrochemische en Chemische Verwerking —— Bestand tegen intergranulaire corrosie na het lassen

----------------------------------------------------------------------------------------------------------------------------------------------------------------

Waarom kiezen voor onze 316L U-Buizen?

- Volledige Traceerbaarheid: Elke partij materialen heeft een volledig materiaalcertificaat om naleving van normen en specificaties te garanderen.

-

Superieure Vakmanschap: Professionele pijpbuigtechnologie zorgt voor defectvrije U-bochten, waardoor de levensduur van de apparatuur wordt verlengd.

-

Aangepaste Oplossingen: We kunnen precieze, op maat gemaakte productie leveren op basis van uw specifieke tekeningen en technische vereisten.

-

Wereldwijde Certificeringen: Onze producten voldoen aan internationale normen zoals ASTM, ASME en EN en bedienen klanten wereldwijd.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!